Hearing Aid 3D Printer

| Configuration | Floor-Standing |

| Applications | For Hearing Aids |

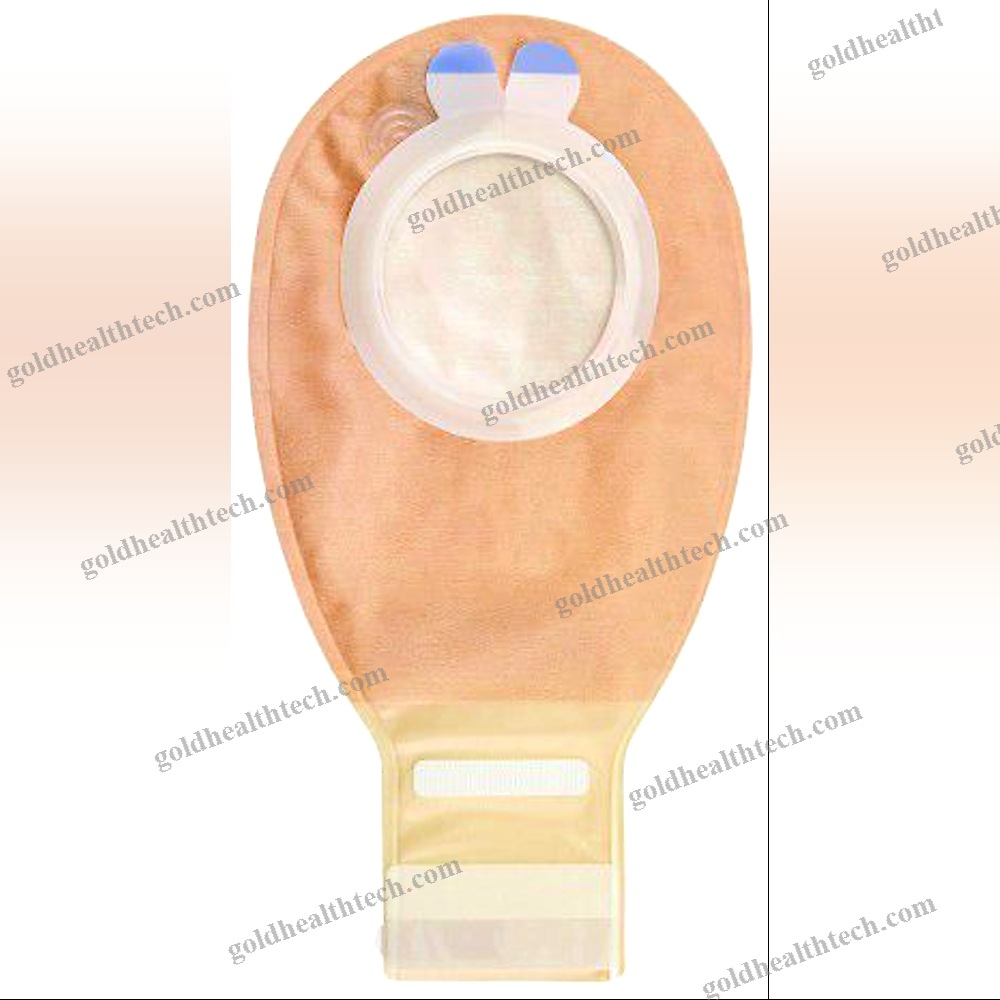

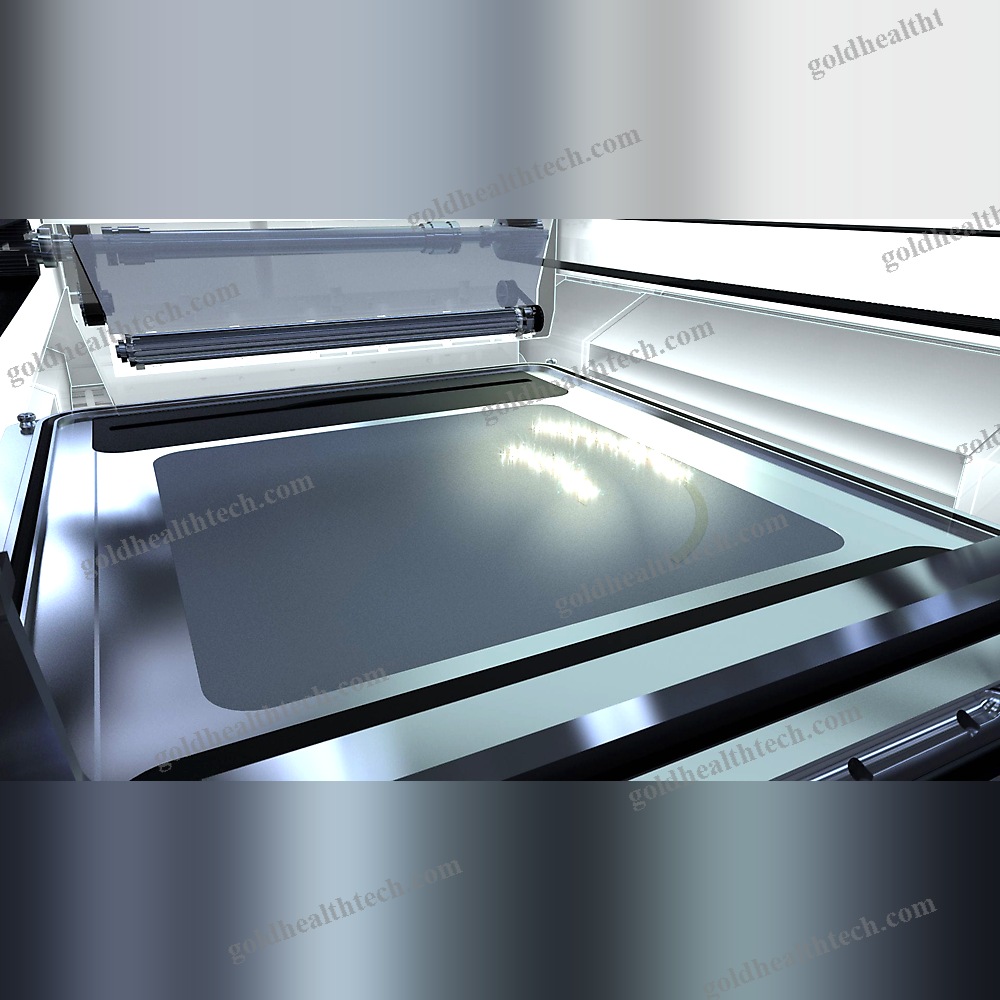

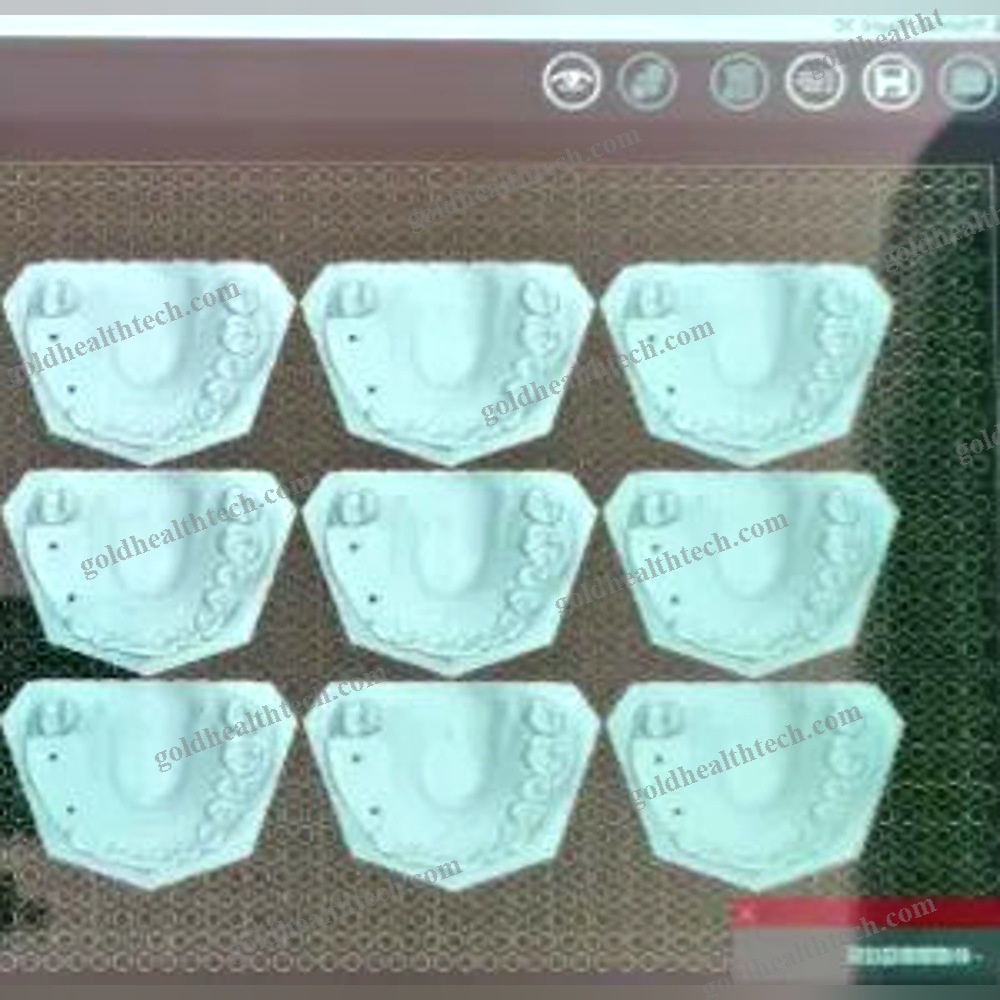

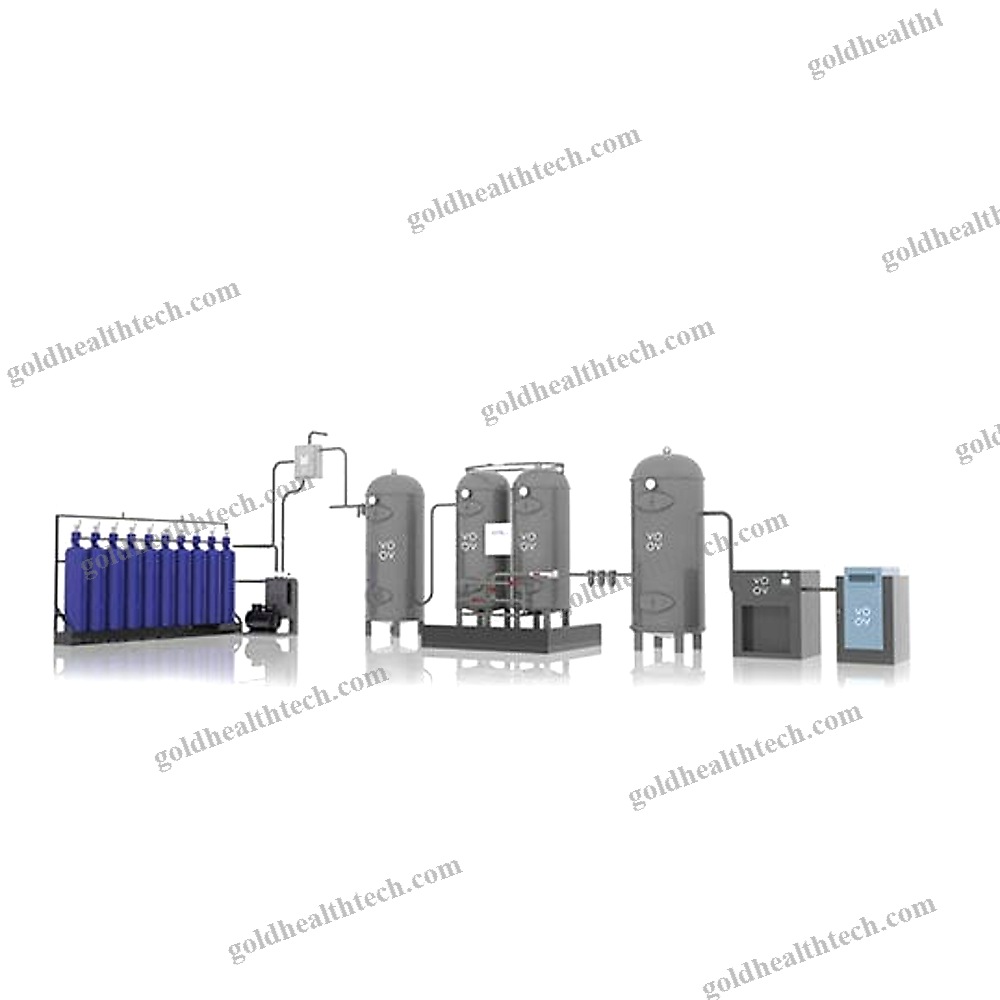

Shell manufacturing is performed with high precision and in short batch cycles, sometimes as short as 45 minutes for a full ITE / ITC shell platform. High accuracy in x/y/z can be achieved by adhering to the standards of the largest hearing aid manufacturers worldwide.

Ear molds and ear protections are produced in batch cycles as short as one hour for a complete platform. The material may be transparent or colored. Due to the effortless exchange of the vat, material substitution is feasible in a rapid manner.

Molds The batch cycle for castings has been reduced to a full platform in one hour. Numerous materials may be implemented. No components that are locked in and an open system architecture. Connectivity with CAD design and support generation software The open resin library allows for easy online updates. Additionally, the open system allows for the continuous development and customization of resins. Training and installation services are accessible. Long-lasting, high-quality components that are serviceable

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.