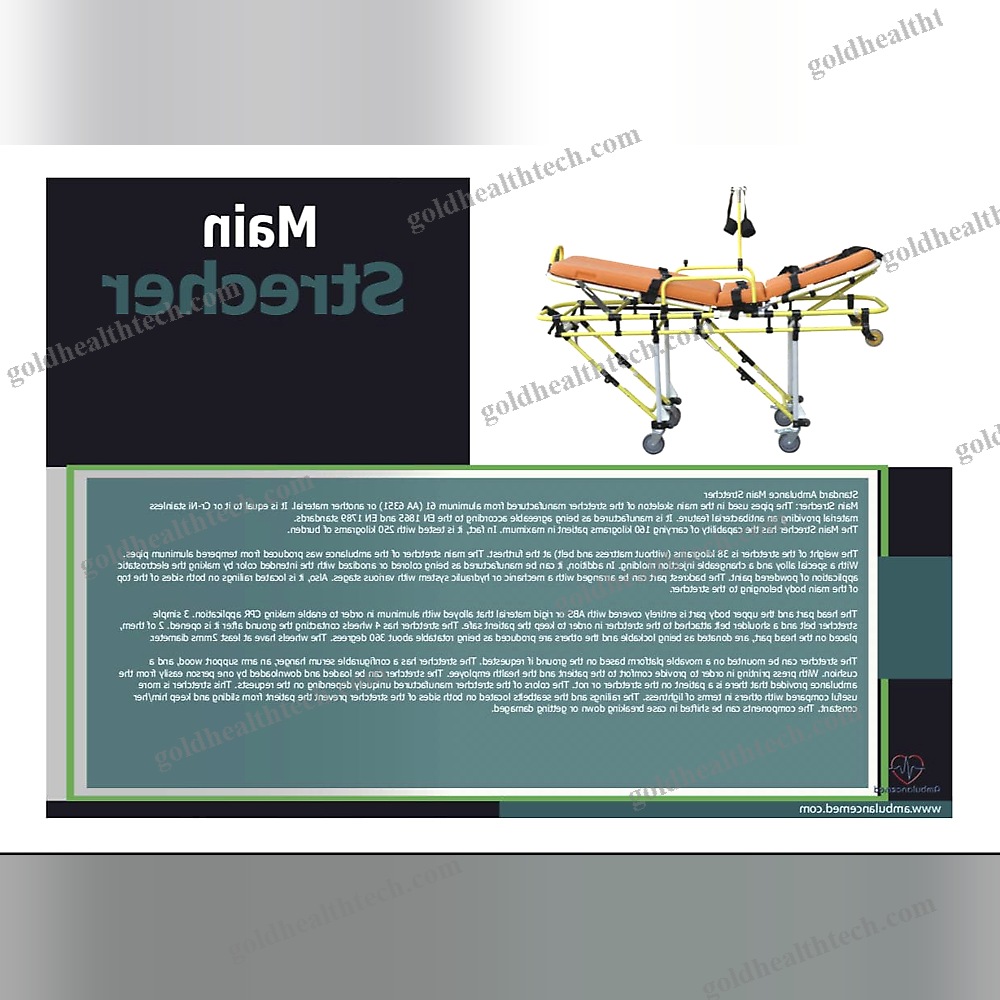

Emergency Stretcher

| Other Characteristics | Aluminum |

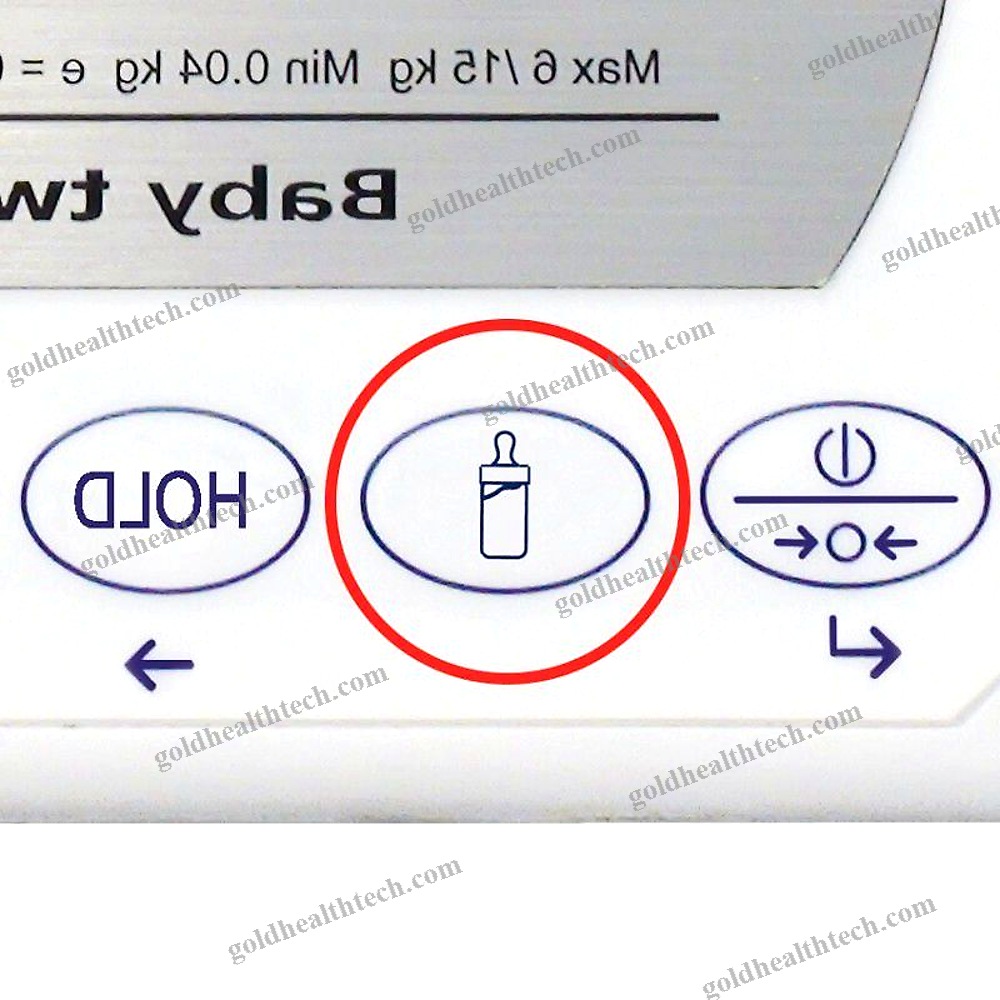

| Patient Type | Pediatric |

| Applications | Emergency |

| Functioning | Radiolucent, Height-Adjustable |

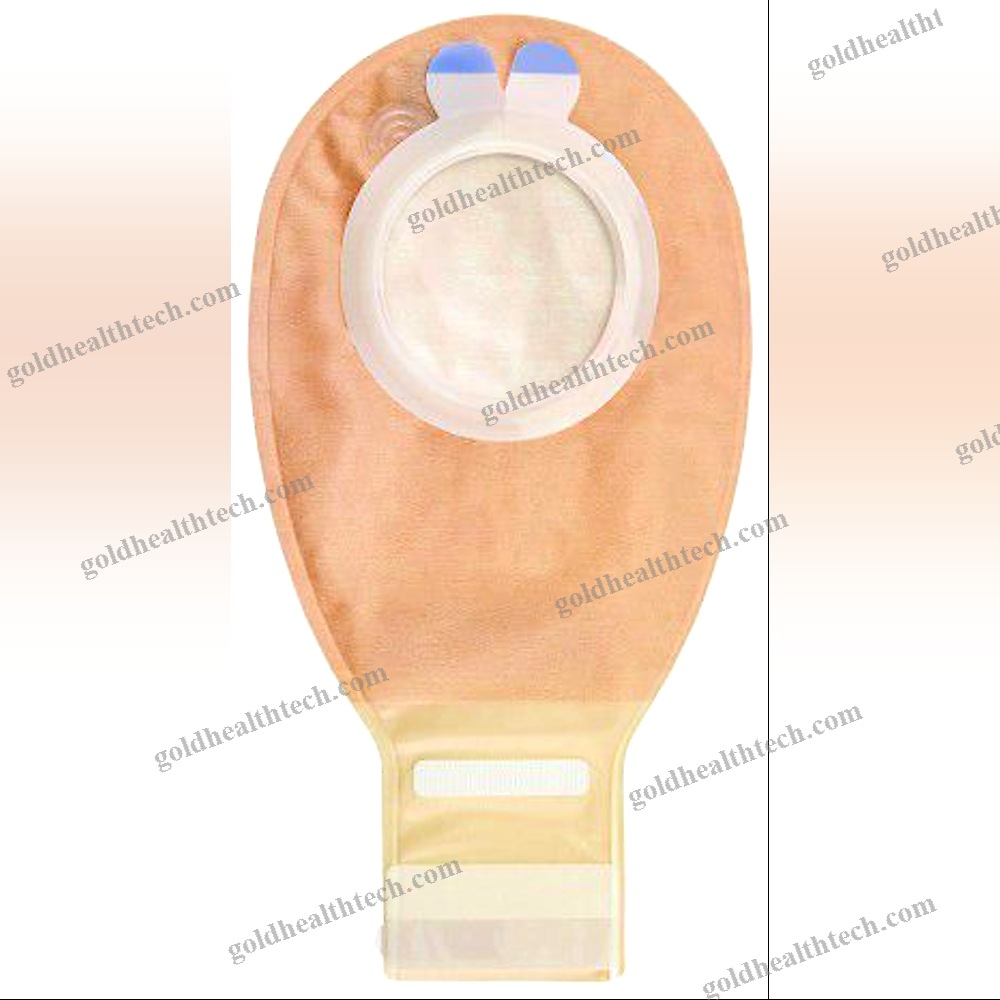

Main Strecher: The pipes that comprise the primary skeleton of the stretcher are constructed from aluminum 61 (AA 6351) or an alternative material. It is comparable to Cr-Ni stainless steel in terms of its antibacterial properties. According to the EN 1865 and EN 1789 standards, it is manufactured to be agreeable.input:

output:Primary Characteristics of Stretchers

The Main Strecher is capable of accommodating a maximum of 160 kilograms of patient. In reality, it undergoes testing with a load of 250 kilograms.input:

output:At its furthest point, the stretcher weighs 38 kilograms (excluding the mattress and belt). Tempered aluminum pipes were employed to fabricate the ambulance’s primary stretcher. Utilizing a unique alloy and a variable injection molding process. Additionally, powdered paint can be electrostatically applied to the product to achieve the desired color or anodize it. A mechanic or hydraulic system with multiple stages can be used to arrange the backrest portion. Additionally, railings are situated on both sides of the stretcher’s main body.input:

output:The head and upper body portions are entirely covered with ABS or a rigid material that has been alloyed with aluminum to facilitate the application of CPR. In order to ensure the patient’s safety, the stretcher is equipped with three basic stretcher belts and a shoulder belt. After it is opened, the stretcher has four wheels that make contact with the ground. Two of them are donated as lockable and are positioned on the head portion. The remaining two are manufactured as rotatable to a maximum of 360 degrees. The wheels have a minimum diameter of 2 millimeters.input:

output:A movable platform can be used to mount the stretcher on the ground, if necessary. The stretcher is equipped with a cushion, an arm support wood, and a configurable serum hanger.

Common Shipping and Delivery Considerations

- Packaging:

Medical devices need secure packaging to avoid damage during transit, including shock-absorbing materials or custom foam inserts. - Compliance with Regulations:

Ensure compliance with local and international standards (e.g., FDA, CE) and shipping regulations like Good Distribution Practice (GDP). - Temperature Control:

Some devices require temperature-controlled shipping (e.g., refrigerated trucks or special packaging) to maintain product integrity. - Tracking and Documentation:

Shipments should be tracked with necessary documents like invoices, certificates, and import/export paperwork. - Lead Time:

Plan ahead for lead times, which can vary depending on the equipment size and delivery location. - Insurance: Due to the high value of medical equipment, consider insurance to protect against loss or damage during transit.

- Customs and Import Regulations: Account for customs procedures and tariffs when shipping internationally, ensuring proper documentation.

- Special Handling:

Fragile or hazardous medical devices may require special handling, with clear labeling to ensure proper care. - Delivery Method:

Choose the appropriate shipping method (air, sea, or ground) depending on the equipment’s size, value, and urgency. - Returns and Reverse Logistics:

Have a clear process in place for returns, repairs, and warranty claims if necessary.