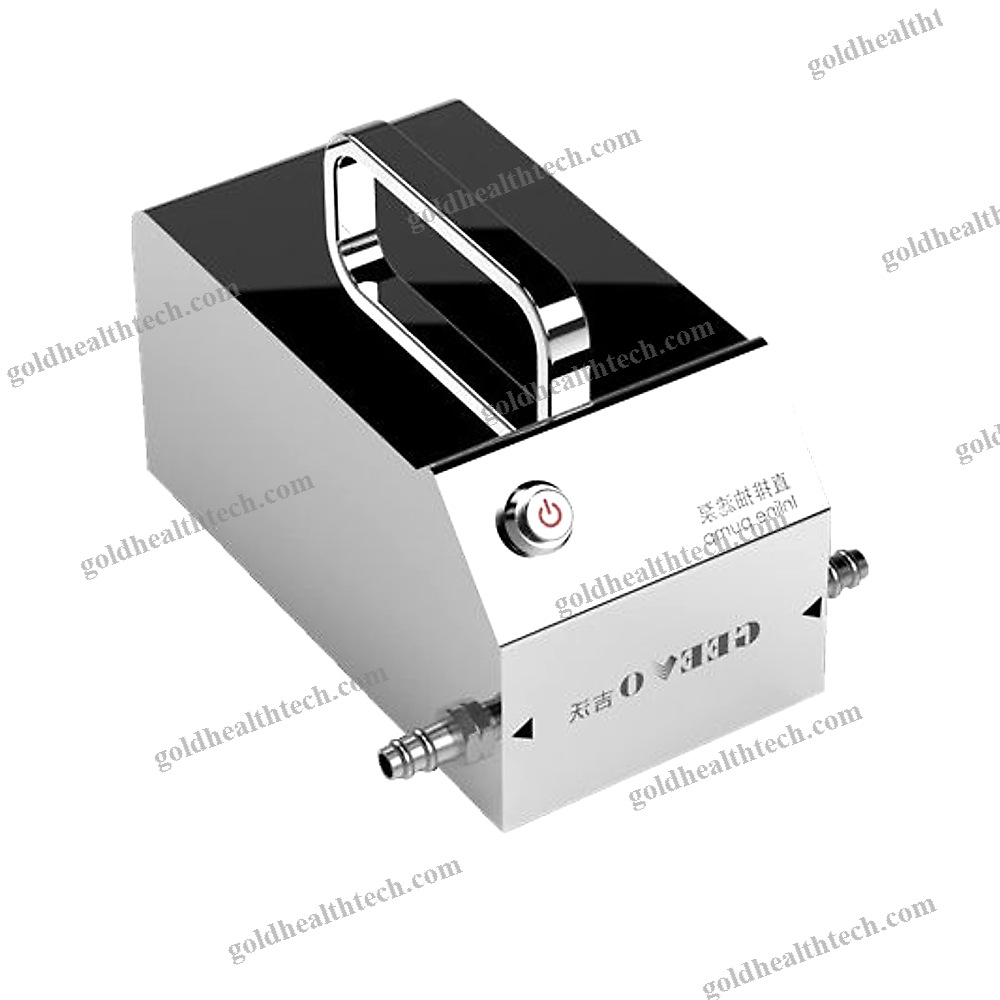

Dental Centrifugal Casting Machine

| Operation | Centrifugal |

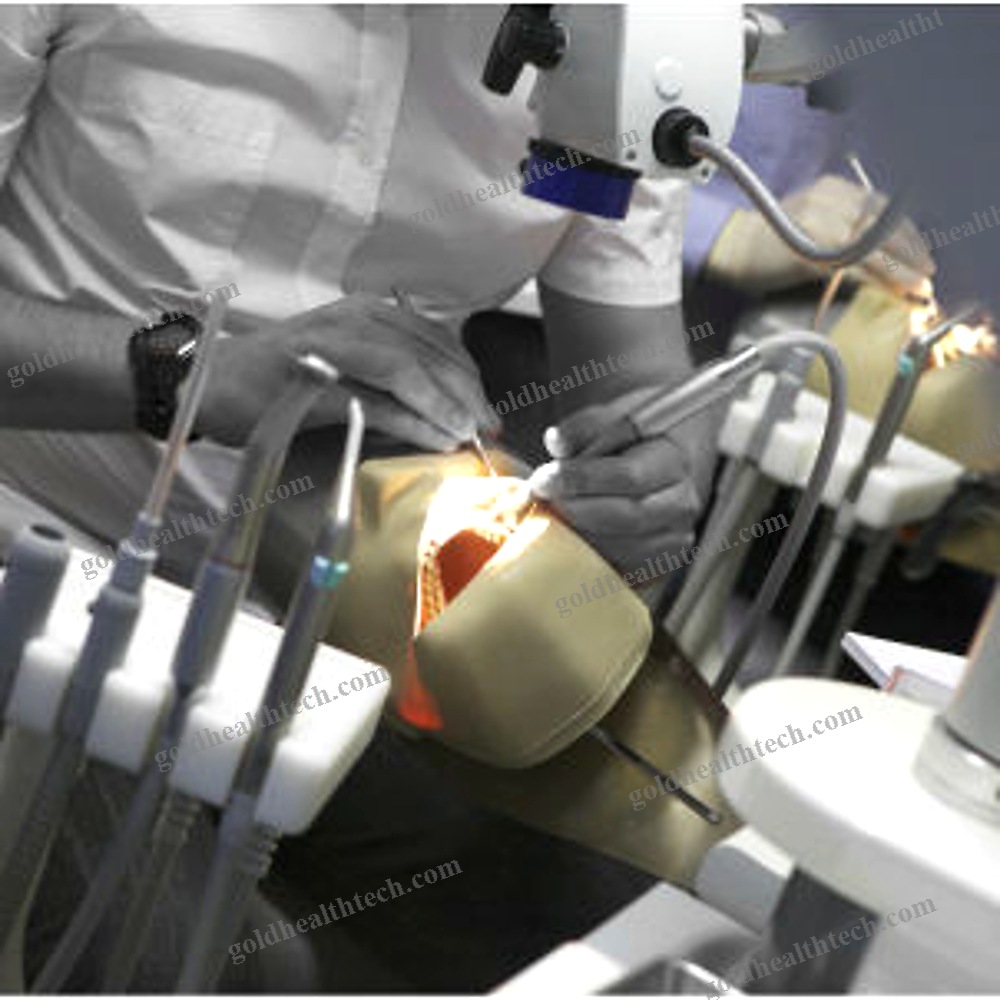

In the prosthodontics department, manual centrifugal casting machines are frequently employed as technical equipment. It is no longer necessary to use a crucible during the casting process; instead, the alloy material can be directly poured into the cavity of the casting mold after melting. The crank can be quickly turned by hand to complete the casting through centrifugal force, resulting in the production of a variety of brackets, inclusions, crown, and bridge castings.

Characteristics:1. Reliable, user-friendly, and optimal for the production of oral restorations.

2. Easily manages the majority of alloys with high melting points that dentists employ.

3. Easily cast denture frames, inlays, and crown bridges!

4. Includes three cradles and a pair of tongs, as well as a heavy-duty spring and an adjustable balance mechanism.input:

output:Details:Dimensions of the product: 37 cm x 37 cm x 27 cm

Dimensions of the package: 40 cm x 23 cm x 23 cm

Weight: 6 kilogramsThe maximum diameter of rotation is 360mm.Maximum spring torque:150 Newtons

The maximum eccentric weight is as follows:1.25 kilograms

The mold’s maximum diameter is 78mm.

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.